What is Possible?

Nakanishi Vision engineers push the limits of what is possible. Through innovative technology, materials, processes and a heritage of precision craftsmanship, art is elevated to functional design.

Purpose Engineered

Working closely with the design team, products are engineered with purpose and manufacturability in mind. Knowing the limits of what is achievable with current technology combined with innovative thinking make market forward concepts a reality.

Engineering Tasks

We work together on detailed tasks to realize the customer’s design and concept.

Design concept review

Reviewing shape, construction, function, material, and manufacturability with the client is essential before we move forward with the technical drawing.

Prototyping

After the technical drawing is approved, we create a handmade prototype sample and receive feedback from the client.

Production arrangements

Once the design is locked, the final approval of the technical drawing is done, and we move on to tooling arrangements, creating a tooling sample, color sample, sales sample, and so on, before starting mass production.

Titanium

-

Half the weight of nickel or silver

-

Nickel-free and naturally corrosion free

-

Higher manufacturability for complex shapes and an enhanced design

-

Rim-wire bending and punch-out

-

Supports various surface treatments and color options

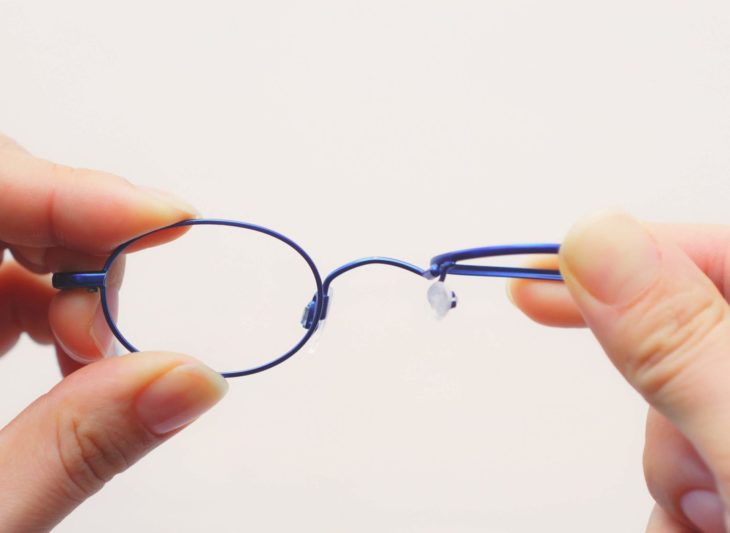

Memory Metal

-

Nakanishi was the first to apply this material in the eyewear industry, leveraging the springiness, flexibility, and shape memory characteristics for comfort and durability.

-

Great fit, durability, and shape retention

Acetate

-

The highest quality Japanese and Italian-made acetate sheet with various color patterns.

-

Handcrafted and polished every piece

-

Unrivaled material longevity

Plastic Injection

-

Single injection frame

-

Various materials – Nylon, Rubber….

-

Plant based material for sustainability

-

Integrate two materials, nylon or rubber

-

Organic design and flexibility

-

Reflective finish polishing and sandblasting finish for the satin look and feel.

-

Plastic and metal co-injected in one process

CAD/CAM software used for design, modeling and manufacturing engineering

Design

Collaborative, purpose-based design helps to create original, functional works of art

More

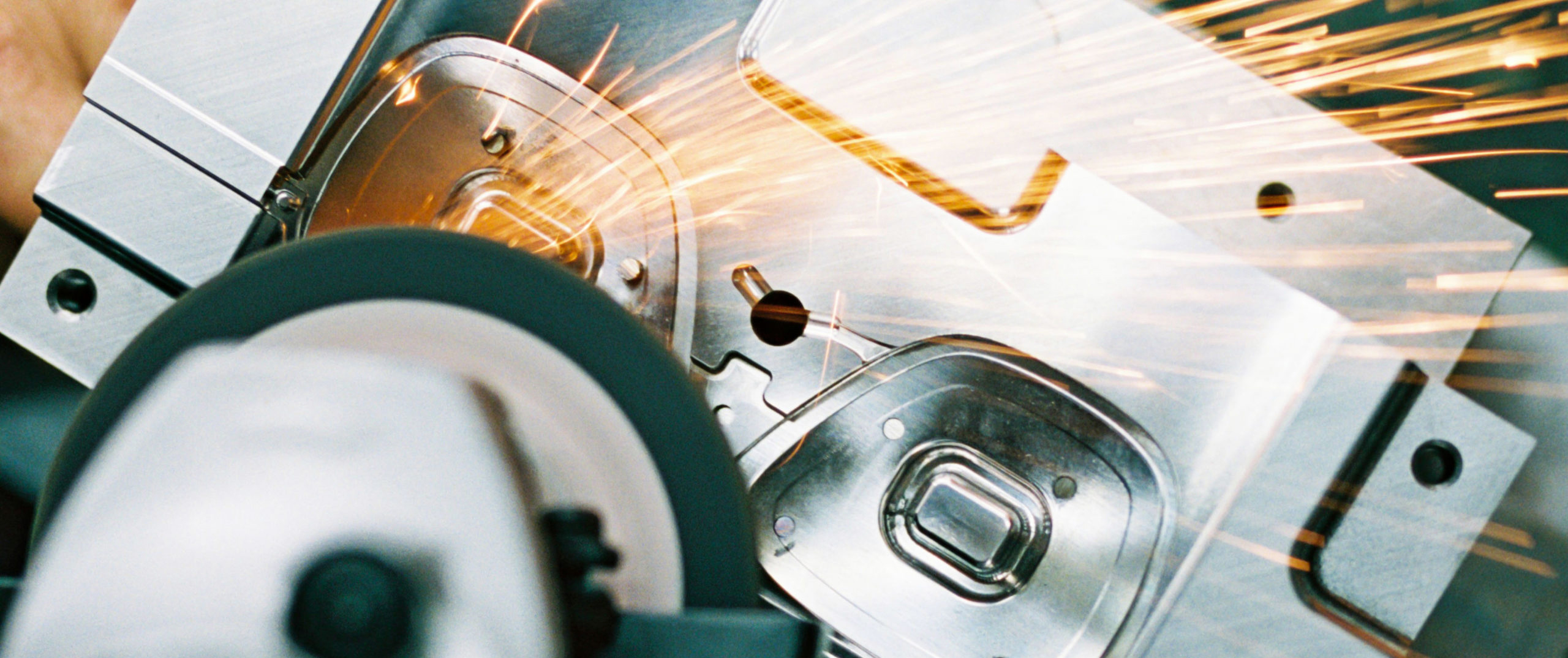

Engineering

Innovation, technology, materials and processes push the limits of what is possible

More

Manufacturing

The most advanced manufacturing technology is used to create every collection

More

Quality

Quality is about pride of workmanship; every product reflects a commitment to producing the very best

More

People First

A strong sense of team and purpose drives a culture of innovation, quality and accountability

More