Craftsmanship

Nakanishi Vision utilizes advanced manufacturing technology to produce every collection, but at the end of the day it all gives way to time honored craftsmanship, with attention given to every detail – there is no easy way, only the right way.

Manufacturing Engineering

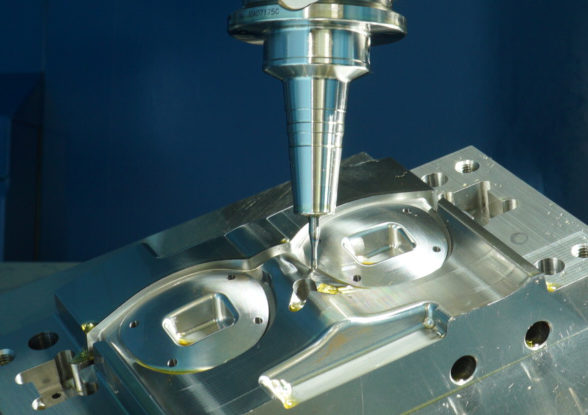

The team is the backbone of producing high-precision, high-quality frames and is the accumulation and foundation of Nakanishi’s many years of experience and know-how.

Molds are the basis of manufacturing, whose technical level determines the superiority of product appearance, quality, performance, and even productivity. Nakanishi Vision uses the latest 3D CAD/CAM system to design and 5-axis and 3-axis CNC to produce the mold.

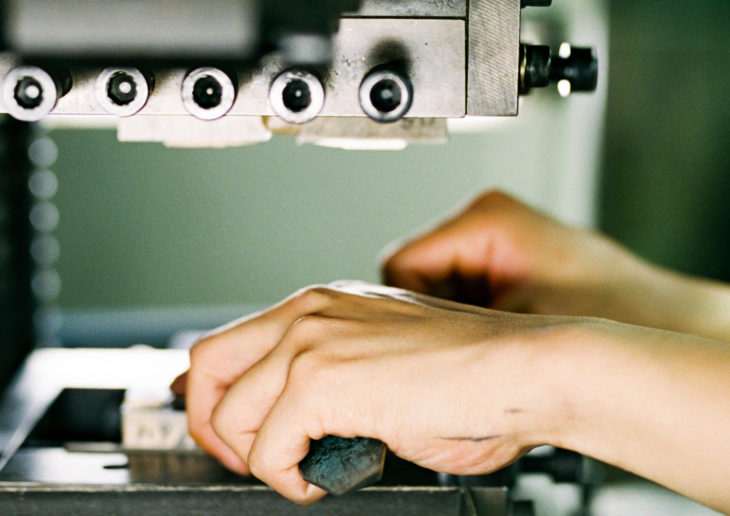

In-house developed jigs play an important role in supporting the processing, assembling, and inspection of products with high precision, suppressing variations and productivity.

There are over 250 production steps in the production of titanium frames. As a custom design OEM manufacturer, we create process step documents for all models and styles to optimize manufacturing and produce consistent quality products.

Metal Frame

Titanium material has many advantages. Lightweight without sacrificing strength, safe to use as glasses that touch the body, and resistant to rust. But its greatest disadvantage is that it is difficult to press, cut, drill, bend, and even weld due to its chemical property.

Japan leads the world in Titanium press processing technology.

A craftsmanship process that uses precision molds and repeats press work to finish the shape according to the drawing. The pressing process also increases the strength of the parts.

Based on the design, a series of fabrications, such as cutting, drilling, and bending of parts, and brazing work to weld each piece. These steps require high precision with advanced equipment, including CNC machining centers and laser welding machines, relying on precise techniques that do not allow even the slightest deviation.

Polishing technology supports world-class beauty. It is carefully buffed by hand, and further polished with barrel polishing. Depending on the surface shape and material characteristics, subtle adjustments are made while polishing to bring out the luster.

Surface treatment affects the brilliance of gold and silver, which shines beautifully. Plating and painting are applied to materials polished over a long period. Advanced surface treatment technology and the hands of craftsmen enable a variety of coloring expressions.

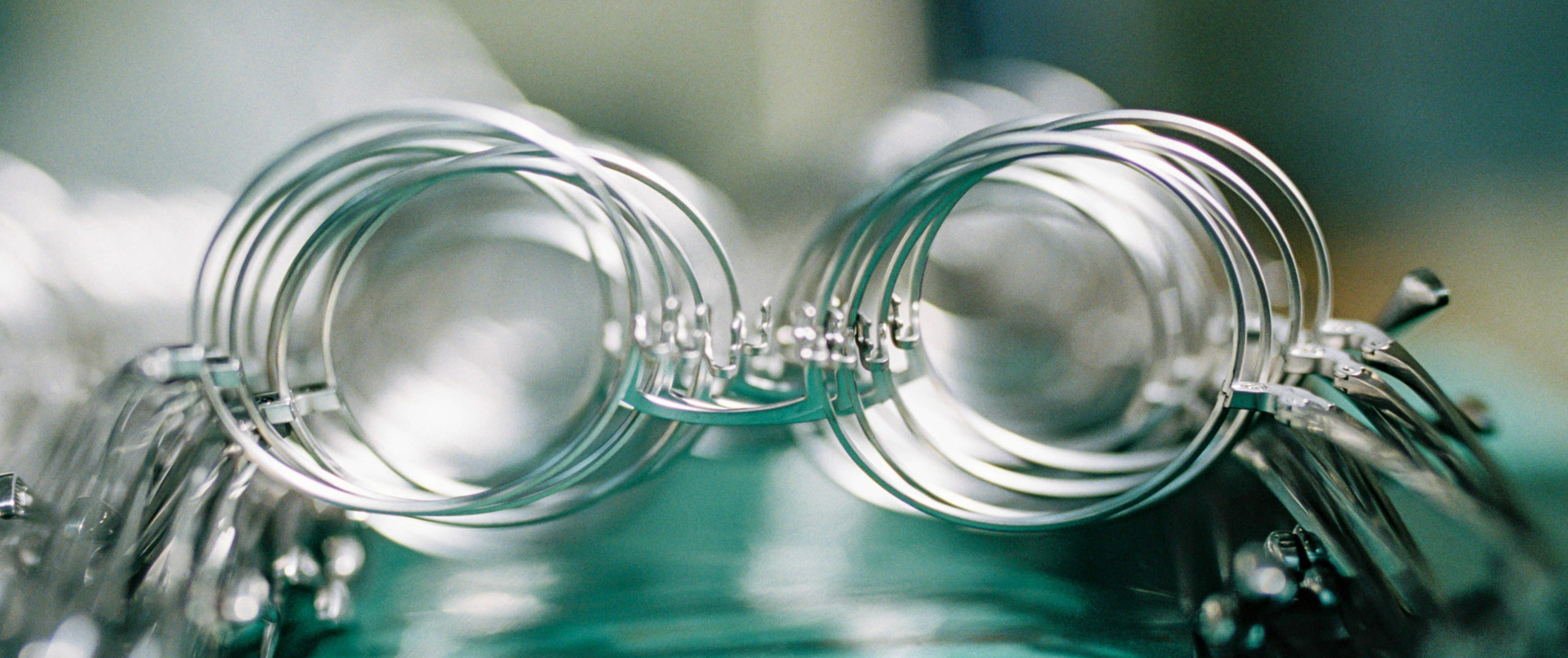

Acetate Frame

Acetate material is made from natural cellulose and is an environmentally friendly material. With its smooth texture, rich, translucent color, and patterns, Japanese acetate is particularly popular among global brands.

Nakanishi Vision uses the latest 3-axis and 5-axis CNCs to process acetate sheets according to the design. Computer control realizes accurate and complex shapes.

A lengthy polishing process, shaving the surface of a product to “make unevenness smooth” and the surface to a shine through micron-level adjustments, bringing the acetate extraordinary brilliance and beauty.

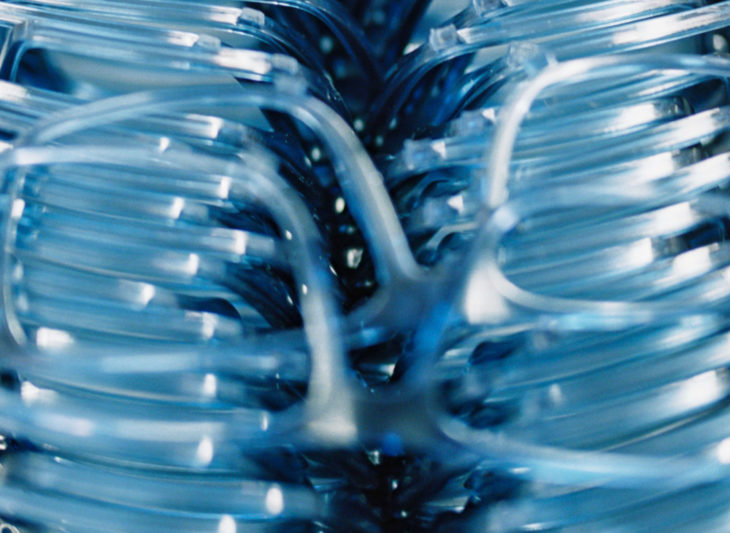

Plastic frame

Injection molding is the process in which the heated resin is poured into a mold and molded. We have expertise in various resins, including plant-based, and are also capable of “double injection” technology, molding two different materials into one frame.

If the structure is too complex to make with a mold, secondary processing is performed with a machining center.

Buffing removes parting lines (burrs), and polishing is performed to bring out the luster. We are also working on recycling waste materials.

Assembly/Finishing

Craftsmen carefully assemble each part by hand using various parts/components made of metal, plastic, and acetate.

Adjusting the assembled frame, the opening, and folding conditions one by one so that each frame has the same finish.

After cleaning the finished frame, a skilled worker conducts a strict visual inspection to ensure no scratches or defects.

Highly specialized machines developed to help automate manufacturing

Design

Collaborative, purpose-based design helps to create original, functional works of art

More

Engineering

Innovation, technology, materials and processes push the limits of what is possible

More

Manufacturing

The most advanced manufacturing technology is used to create every collection

More

Quality

Quality is about pride of workmanship; every product reflects a commitment to producing the very best

More

People First

A strong sense of team and purpose drives a culture of innovation, quality and accountability

More